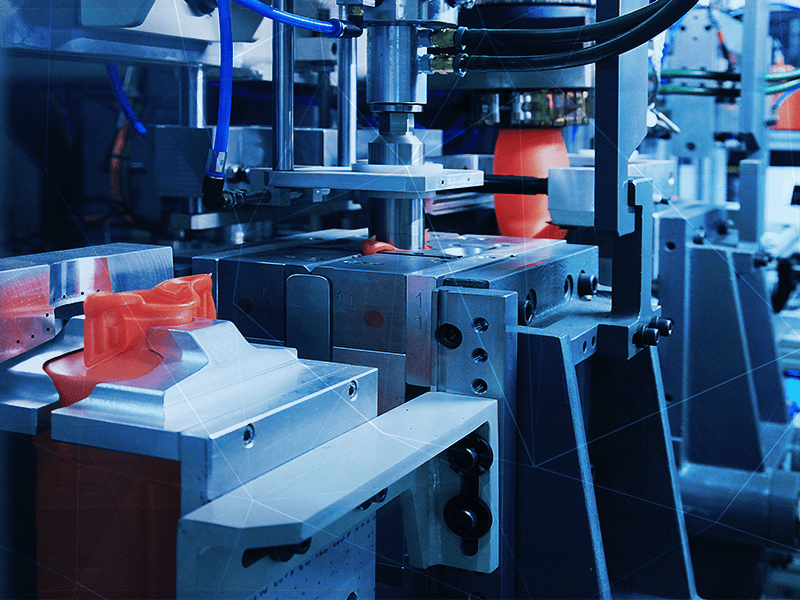

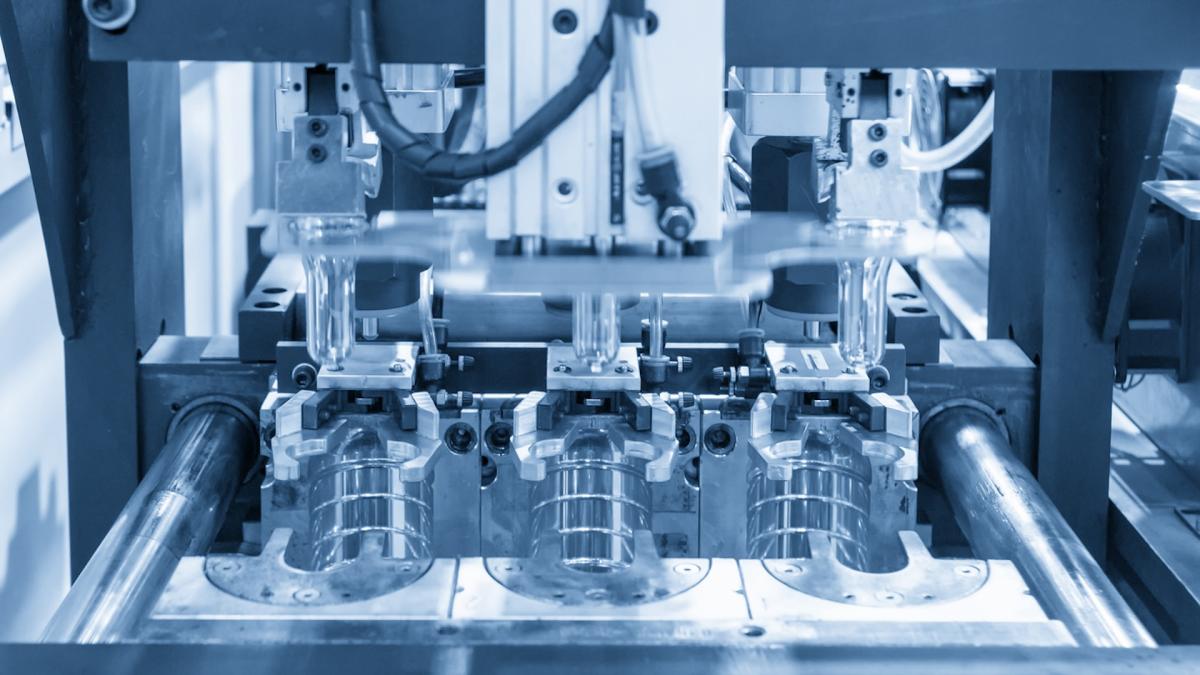

Capabilities You Can Count On

Our manufacturing capabilities are built around one thing: delivering precision plastic products, on your timeline, to your exact standards. We serve clients in demanding sectors — and we match that demand with world-class tools and processes.